français

français English

English

Español

Español

Português

Português

русский

русский

français

français

日本語

日本語

Deutsch

Deutsch

Tiếng Việt

Tiếng Việt

Italiano

Italiano

Nederlands

Nederlands

ไทย

ไทย

Polski

Polski

한국어

한국어

Svenska

Svenska

magyar

magyar

Malay

Malay

বাংলা

বাংলা

Dansk

Dansk

Suomi

Suomi

हिन्दी

हिन्दी

Pilipino

Pilipino

Türk

Türk

Gaeilge

Gaeilge

عربى

عربى

Indonesia

Indonesia

norsk

norsk

اردو

اردو

čeština

čeština

Ελληνικά

Ελληνικά

Українська

Українська

Javanese

Javanese

български

български

Latine

Latine

Azərbaycan

Azərbaycan

slovenský

slovenský

Lietuvos

Lietuvos

Eesti Keel

Eesti Keel

Română

Română

Slovenski

Slovenski

Српски

Српски

Afrikaans

Afrikaans

Cymraeg

Cymraeg

icelandic

icelandic

Беларус

Беларус

Hrvatski

Hrvatski

ქართული

ქართული

Кыргыз тили

Кыргыз тили

Zulu

Zulu

O'zbek

O'zbek

Lëtzebuergesch

Lëtzebuergesch

Are vou looking for a case that can protect your delicate devices or sensitive instruments?

A thermoformed EVA case is an idea solution.

Due to its duraility. pressure resistance and ioht portaiity, EVA cases offer perfect alteative to hard plastic cases and aluminum case.

With low tooling cost, an EVA foam can be molded to any shape, any size you want.

it's unique thermoforming process can create better and diversified form of EVA hard shell cases

Features & Benefits of EVA Cases:

- - Low tooling costs

- - Easier to shape & low rejection rate

- - Variety of colors

- - Lightweight portability with protection of a hard case

- - To offer security against impact, dust, sun, moisture and other environmental stresses

- - Eco-friendly

Because of these characteristics, EVA cases are widely used in various fields,

Such as:

Can't Find The EVA Case For Your Application?

lf you can imagine it,we can make it.

Talk About Your Custom Needs-

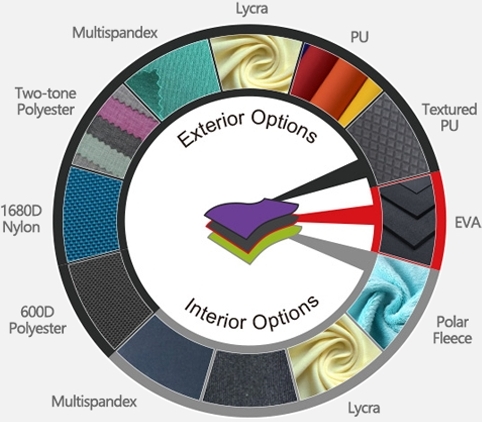

EVA Shell Customization

Stand Out With Fully-Customized Outer Shell

At Dong Case, we offer numerous custom choices for you to create the outershell of your EVA case.

With strong molding capability, we can make your case into any shape asrequired. Depending on the content inside, you have the choice to make yourcase softer or harder with EVA featuring different density. And a lot of optionsfor exterior and lining materials are available based on your target marketsand budget.

A fully-customized out shell ensures that your product/ delicate equipmentalways stands out with a stylish look while being fully protected.

-

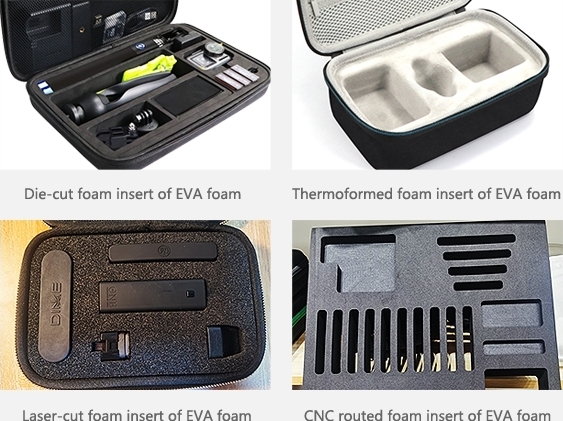

Foam Insert Customization

High protection starts from custom-fit foam insert

Custom made foam inserts prevent your products from sliding around in anEVA case, and hold everything exactly in its place.

At Dong Case, we can offer customized foam inserts below:

1. Die-cut foam insert of sponge foam / EVA foam / EPE foam

2. Laser-cut foam insert of EVA foam / EPE foam

3. Thermoformed foam insert of EVA foam

4. CNC routed foam insert of EVA foam

Talk About Your EVA Foam Custom Needs

Logo Customization

lmprove Brand Awareness With Custom Logo

One of the important components of a brand is the logo because as the "face' of the business, a prefect logo can make customers remember.

A custom logo on your EVA case makes your products uniquely yours and helps to improve your brand awareness.

Depending on your logo design, your brand identy, and your budget, we ofer a wide range of ways to put your logo on the case shel, zipper, or label.

From printing to embossing to embroidery, you can choose the one that best shows your logo and brand.

Zipper & Puller Options

The perfect zipper gives you a very nice sense of experience, and the puller highlights its brand.

The zipper is an important part of the quality of a case.

So, we pay great attention to the choice of zipper!

Exterior Accessories Options

Know Our Factory

One-stop EVA Case Custom Professional Production Process

Our factory has complete equipment. There is a full set of workshops, including CNCmold workshop,laminating workshop, molding workshop, the thermoformingworkshop, stitching workshop, cutting workshop, and packaging workshop.

A specialized worker will be responsible for every step in our EVA case production toensure the quality of every detail.